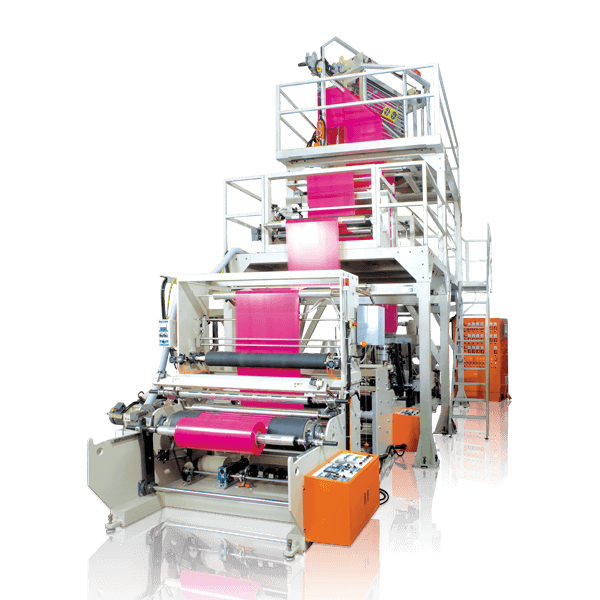

| MODEL | KMTL-40-45-40 E3 | KMTL-45-55-45 E3 | KMTL-55-65-55 E3 |

| SUITABLE MATERIAL | HDPE/ LDPE/ LLDPE/ mLDPE | HDPE/ LDPE/ LLDPE/ mLDPE | HDPE/ LDPE/ LLDPE/ mLDPE |

| FILM THICKNESS | 0.02-0.15 mm | 0.025-0.20 mm | 0.03-0.20 mm |

| FILM WIDTH RANGE | 900 mm | 1400 mm | 1800 mm |

| FILM OUTPUT | 110 kgs/hr | 150 kgs/hr | 250 kgs/hr |

| EXTRUDER UNIT | |||

| SCREW DIAMETER/TYPE | Ø 40-45-40 mm | Ø 45-55-45 mm | Ø 55-65-55 mm |

| SCREW L/D RATIO | 28:1 | 28:1 | 28:1 |

| HEATING CAPACITY | 24.6 kw | 34.3 kw | 43.7 kw |

| AUTO THERMO CONTROL | 11 zone | 13 zone | 17 zone |

| BARREL COOLING FAN | 1/8 HP x 6 | 1/8 HP x 9 | 1/8 HP x 9 |

| DRIVING MOTOR | AC 15-20-15 HP + Inverter | AC 20-30-20 HP + Inverter | AC 30-50-30 HP + Inverter |

| DIE UNIT | |||

| DIE DIAMETER | Ø200 mm | Ø300 mm | Ø500 mm |

| AIR RING DIAMETER | Ø250 mm | Ø350 mm | Ø550 mm |

| HEATING CAPACITY | 19.8 kw | 24.6 kw | 28.8 kw |

| AUTO THERMO CONTROL | 3 zone | 4 zone | 4 zone |

| COOLING BLOWER | 5 HP | 7 1/2 HP | 10 HP |

| TAKE-UP UNIT | |||

| TAKE-UP ROLLER | 1100 mm | 1600 mm | 2000 mm |

| EFFECTIVE WIDTH | 900 mm | 1400 mm | 1800 mm |

| TAKE-UP MOTOR | AC 1/2 HP | AC 1 HP | AC 2 HP |

| TAKE-UP SPEED | 65 m/min | 45 m/min | 40 m/min |

| WINDING UNIT | |||

| ROLLER WIDTH | 1100 mm | 1600 mm | 2000 mm |

| WINDING WIDTH | 900 mm | 1400 mm | 1800 mm |

| WINDING MOTOR | DC 1 HP | DC 1 HP | DC 2 HP |

* Remark: The above machine specification and production range can be changed without any notice due to kind of different application.

| OPTIONAL EQUIPMENT |

| 1. OSCILLATING HAUOFF (270 DEGREE ROTATION). |

| 2. ROTATING DIE (CONTINUOUS 360 DEGREE ROTATION). |

| 3. EDGE POSITION CONTROL (EPC). |

| 4. FILM TENSION CONTROL. |

|

5. PROGRAMMABLE LOGIC CONTROL ( PLC ) COMPUTER SYSTEM WITH SERVO MOTOR DRIVING OPERATION. |

| 6. AIR CHILLER & HEAT EXCHANGER FOR AIR COOLING OPERATION. |

| 7. EXTRUSION PRESSURE INSPECTING METER. |

| 8. AUTO LOADING OF HOPPER SYSTEM FOR RAW MATERIAL. |

| 9. BACK TO BACK WIDER. |

| 10.FILM SURFACE TREATER. |