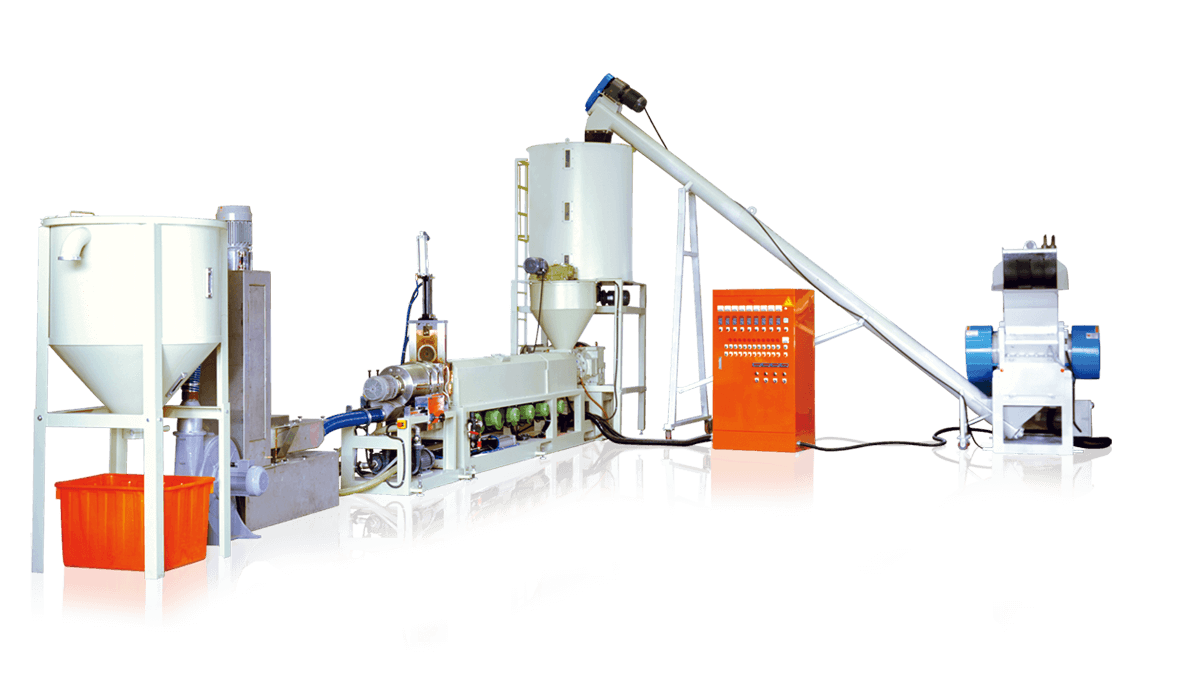

| MODEL | KCR-120 |

| SUITABLE MATERIAL | HDPE/LDPE/LLDPE |

| OUTPUT | 200-300 kgs / hr |

| CRUSHER & SCREW CONVER SYSTEM | |

| CRUSHER | 30 HP |

| SCREW CONVER | 2 HP |

| INTO SIZE | 5" |

| EXTRUDER | |

| WASTE COLLECTING TANK | 1400 L |

| COLLECTING TANK MOTOR | 2 HP + Inverter |

| SPIRAL TYPE FEEDING DEVICE FOR HOPE | 2 HP + Inverter |

| GEAR BOX | Direct Connect Type |

| SCREW DIAMETER |

Ø 120 mm Single Dega Sification |

| SCREW L/D RATIO | 30:1 |

| HEATING CAPACITY | 80.8 kw |

| AUTO THERMO CONTROL | 7 zone |

| DRIVING MOTOR | AC 100 hp + Inverter |

| DIE FACE CUTTING & SCREEN CHANGER | |

| DIE TYPE | Circular Shape Extrusion Die |

| HEATER | 13.4 kw |

| AUTO THERMO CONTROL | 2 zone |

| PELLETIZING | 2 PCS(SPRING) |

| PELLETIZING MOTOR | 1 HP + Inverter |

| SCREEN CHANGER | Hydraulic Cylinder |

| COOLING SYSTEM | |

| TYPE | Water Cooling |

| COOLING WATER DRUM | 1 Set |

| WATER PUMP | 2 HP x 2 |

| COOLING WATER TANK | 1 Set |

| DEHYDRATOR & CENTRIFUGAL SEPARATOR SYSTEM | |

| DEHYDRATOR | 1 Set |

| DEHYDRATOR MOTOR | 5 HP |

| COLLECTING SYSTEM | |

| AIR BLOWER | 5 HP |

| COLLECTING TANK | 600 L |

| PELLET CUTTING MACHINE | |

| MOTOR | - |

| CUTTER MOTOR | - |